Tips for Maintaining Heavy Equipment

November 8, 2024 2:30 pm Leave your thoughtsMaintaining heavy equipment is essential for companies in construction, mining, agriculture, and various other industries. Proper maintenance extends the lifespan of the machinery, ensures safety, reduces downtime, and minimizes costly repairs. To get the best performance and reliability from your heavy equipment, adopting a thorough and consistent maintenance strategy is key. Here, we’ll cover essential heavy equipment maintenance tips to help you keep your machinery in top condition.

The Importance of Regular Maintenance

Maintaining heavy equipment is more than just a task on a checklist; it’s a practice that directly impacts the success and efficiency of your operations. Heavy equipment that is neglected can lead to serious and costly issues, from mechanical failures to safety hazards for operators. Regular maintenance helps identify small issues before they turn into major problems, saving time, money, and potentially lives.

Benefits of Maintaining Heavy Equipment

- Extended Lifespan: Regular maintenance can help extend the lifespan of machinery, maximizing the return on investment.

- Increased Efficiency: Well-maintained equipment runs more efficiently, which can help reduce fuel costs and improve overall productivity.

- Reduced Downtime: Addressing maintenance needs early helps prevent unexpected breakdowns and production delays.

- Improved Safety: Routine inspections and repairs ensure that the equipment is safe to operate, reducing the risk of accidents on-site.

Essential Heavy Equipment Maintenance Tips

Conduct Regular Inspections

One of the most important heavy equipment maintenance tips is conducting thorough and regular inspections. Regular inspections help detect potential problems before they escalate and ensure that all components are in working order. Inspections should cover all critical aspects, including:

- Fluid Levels: Check hydraulic, coolant, engine oil, and fuel levels.

- Wear and Tear: Inspect parts prone to wear, like hoses, belts, and tires.

- Electrical Systems: Examine the battery, wiring, and connections.

- Hydraulic Systems: Look for leaks, cracks, and unusual sounds.

Frequent inspections create a baseline for equipment condition, making it easier to spot any unusual changes over time.

Follow Manufacturer’s Guidelines

Every piece of equipment comes with a manufacturer’s manual detailing its specifications, maintenance requirements, and recommended servicing schedules. Following these guidelines is crucial to ensure you’re maintaining the equipment correctly. The manufacturer’s instructions specify oil change intervals, filter replacements, and other preventive maintenance tips specific to the model.

Why Manufacturer’s Guidelines Matter

- Warranty Compliance: Ignoring manufacturer recommendations can void warranties.

- Optimization: Maintenance guidelines help ensure equipment performs at optimal levels.

- Longevity: Following manufacturer advice often leads to a longer equipment life span.

Keep the Equipment Clean

Heavy equipment often operates in harsh environments, accumulating dirt, dust, and debris, which can damage components if not cleaned off regularly. Cleaning should focus on the exterior, air filters, radiators, and other critical parts that can be affected by debris buildup. Some cleaning methods include:

- Pressure Washing: Ideal for removing thick mud and grime.

- Compressed Air: Use for blowing out dirt in hard-to-reach areas.

- Cleaning Agents: Use mild, non-corrosive cleaners on sensitive parts.

Regular cleaning is a proactive way of preventing blockages, overheating, and accelerated wear on your equipment.

Monitor Fluid Levels and Quality

Fluids are essential to the operation of heavy equipment. Regularly monitoring fluid levels is a crucial step in maintaining heavy equipment because it helps prevent component failures and keeps machinery running smoothly. The following fluids should be checked and replaced as needed:

- Engine Oil: Keeps the engine lubricated, preventing friction damage.

- Coolant: Helps regulate engine temperature.

- Hydraulic Fluid: Ensures smooth movement of hydraulic systems.

- Transmission Fluid: Aids in proper transmission operation.

Also, check fluid quality, as contaminated fluids can damage equipment. Any signs of discoloration, unusual odor, or thickening might indicate contamination or a need for replacement.

Lubricate Moving Parts

Lubrication minimizes friction, reduces wear, and helps prevent components from overheating. Heavy equipment has many moving parts, so keeping them adequately lubricated is essential for smooth operation. Create a lubrication schedule that covers:

- Pins and Bushings: Frequently check and lubricate to prevent wear.

- Bearings: Ensure they’re properly lubricated to avoid seizing.

- Hydraulic Cylinders: Keep them lubricated to avoid friction and wear.

Using the right type of lubricant for each part and application is critical, as incorrect lubrication can cause more harm than good.

Keep Tires and Tracks in Good Condition

Tires and tracks play a vital role in stabilizing heavy equipment and ensuring effective operation on various terrains. Proper maintenance of these components can prevent downtime and enhance safety. Regularly inspect tires and tracks for wear, and address any issues promptly. Key tips include:

- Check Tire Pressure: Low tire pressure can increase fuel consumption and cause tire blowouts.

- Inspect Tracks for Wear: Examine tracks for broken links or worn parts.

- Rotate and Replace as Needed: Follow a rotation schedule and replace tires or tracks when they’re no longer safe or effective.

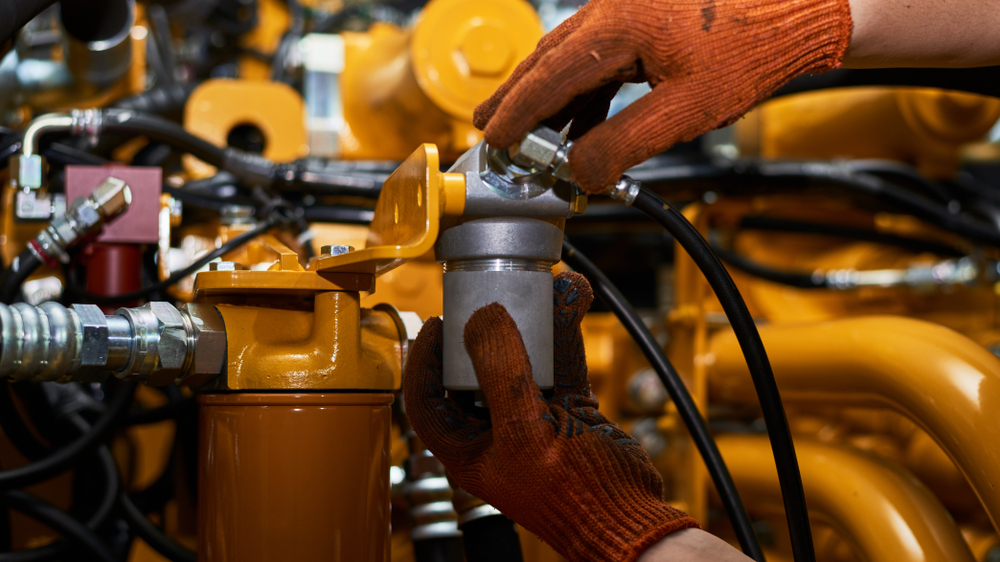

Protect Hydraulic and Electrical Systems

Hydraulic and electrical systems are two of the most critical yet vulnerable components in heavy equipment. Protecting these systems from wear and damage is crucial to maintaining heavy equipment effectively.

- Hydraulic System Tips: Check for leaks regularly and monitor fluid levels. If you notice any unusual noises or reduced performance, address them immediately.

- Electrical System Tips: Inspect wiring and connections for corrosion, and ensure batteries are in good condition.

Keeping these systems in top shape minimizes the risk of major breakdowns and costly repairs.

Maintain a Record-Keeping System

Maintaining records of all inspections, repairs, and maintenance tasks is essential. This history allows operators and maintenance teams to track trends, predict potential issues, and ensure that maintenance is completed on schedule. A record-keeping system should include:

- Inspection Reports: Document findings from regular inspections.

- Service Records: Record all maintenance, repairs, and parts replacements.

- Operator Feedback: Note any issues or unusual observations reported by operators.

Digital record-keeping tools or maintenance management software can streamline this process, making it easier to track and analyze maintenance data.

Train Operators on Maintenance Best Practices

Operators play a critical role in the maintenance process. They are often the first to notice changes in performance or potential issues. Training operators on basic maintenance practices can enhance the effectiveness of your overall maintenance strategy. Key areas for operator training include:

- Daily Inspections: Encourage operators to perform daily checks on fluid levels, tire pressure, and equipment condition.

- Reporting: Train operators to report any unusual sounds, vibrations, or signs of wear.

- Operating Techniques: Teach operators safe and effective techniques to avoid unnecessary wear on the equipment.

Schedule Preventive Maintenance

Preventive maintenance is the practice of scheduling regular maintenance tasks to prevent unexpected equipment failures. Following a preventive maintenance schedule based on the manufacturer’s recommendations is essential. Some preventive maintenance tasks include:

- Routine Oil and Filter Changes: Helps keep engines clean and efficient.

- Inspect Belts and Hoses: Regularly check and replace as needed.

- Check Brakes and Steering: Ensure critical components are in good condition to maintain safety.

Implementing a preventive maintenance plan reduces downtime, enhances equipment reliability, and extends the equipment’s overall lifespan.

Consider Using Maintenance Software

Using maintenance software can streamline the maintenance process and help ensure that no task is missed. Maintenance management software can:

- Schedule Tasks: Automatically set maintenance schedules.

- Track Inventory: Monitor parts and supplies for maintenance.

- Generate Reports: Provide data on equipment performance and maintenance trends.

Software tools help reduce human error, ensuring that maintenance tasks are completed on time and equipment remains in optimal condition.

Final Thoughts

Maintaining heavy equipment requires consistent effort, knowledge, and a proactive approach. By following these heavy equipment maintenance tips, you can reduce downtime, increase safety, and maximize the value of your investment. Regular inspections, lubrication, fluid checks, and operator training are all crucial elements of a successful maintenance strategy. By investing in preventive maintenance and record-keeping, you’re not only ensuring the efficiency and longevity of your heavy equipment but also protecting the well-being of your team and the success of your operations.

With a dedicated approach to maintaining heavy equipment, you can avoid costly repairs, boost productivity, and keep your equipment running smoothly for years to come.

Need a Steel Construction Company in Terre Haute, IN?

Benchmark Fabricated Steel is a premium service provider for all your metal and steel needs since 1971. We offer an array of services and products for commercial, business, and corporation work. Our fully trained team is available for project design, erect drawings, site construction, product procurement and delivery, engineering and consulting, and much more. Benchmark Fabricated Steel is fully accredited by the AISC and the Canadian welding association allowing for the highest quality product to be produced. Our business is also recognized by the Chamber of Commerce and is a fully certified fabricator. All of our products are manufactured by the highest quality of equipment, with an expert and knowledgeable staff. Contact us today to learn more about what we can do for you!

Categorised in: Heavy Equipment Maintenance

This post was written by admin