Non-Ferrous Versus Ferrous Metals

January 3, 2025 4:46 pm Leave your thoughtsWhen it comes to materials used in manufacturing, construction, and a variety of industrial applications, metals are some of the most important components. Understanding the difference between ferrous and non-ferrous metals is essential for choosing the right material for a specific job. In this blog, we will explore the differences between ferrous and non-ferrous metals, their characteristics, applications, and advantages.

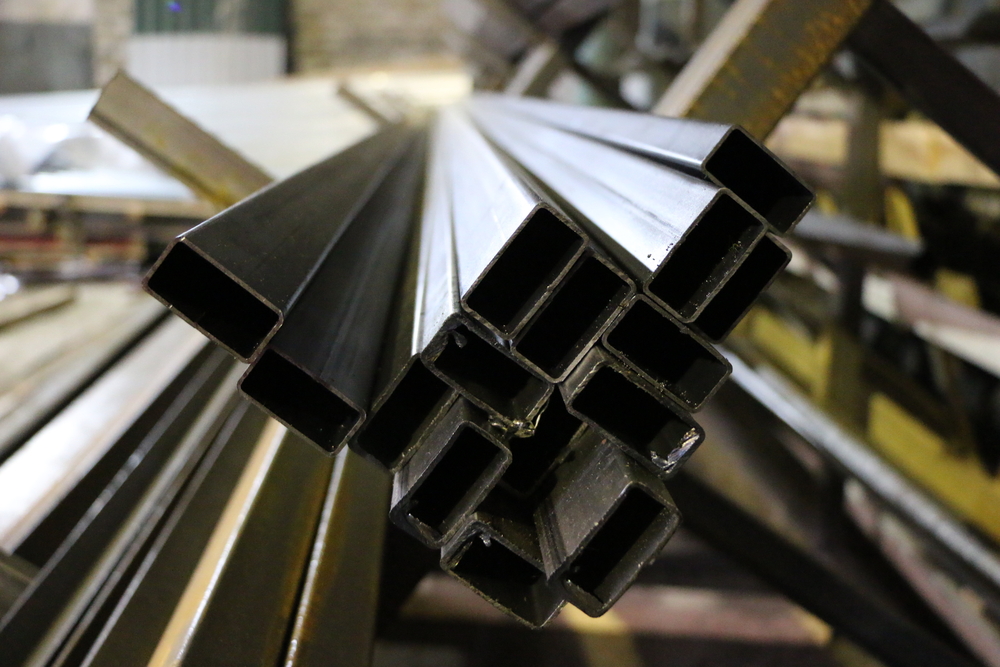

What Are Ferrous Metals?

Ferrous metals are metals that contain iron as their primary element. These metals are characterized by their magnetic properties and tendency to rust when exposed to moisture. The word “ferrous” is derived from the Latin word for iron, “ferrum,” which explains why iron is at the core of this group of metals.

Types of Ferrous Metals

Ferrous metals can be divided into two main categories: carbon steels and alloy steels. Carbon steels are made primarily of iron and carbon, with small amounts of other elements. They are further classified based on the carbon content, which affects their strength and hardness. Alloy steels, on the other hand, are made by adding other elements like chromium, nickel, or manganese to iron to enhance certain properties such as resistance to corrosion or increased strength.

Properties of Ferrous Metals

Ferrous metals are typically strong and durable, which makes them ideal for structural applications. However, they are also prone to rusting when exposed to moisture and oxygen, as iron reacts with water and oxygen to form iron oxide, commonly known as rust. To counteract this, ferrous metals are often treated with coatings or alloys to improve their resistance to corrosion.

Ferrous metals are also magnetic, making them useful in a range of applications where magnetism is required. They are generally more affordable than non-ferrous metals, making them an attractive choice for many industries.

What Are Non-Ferrous Metals?

Non-ferrous metals, in contrast, do not contain significant amounts of iron. These metals are typically more resistant to corrosion, are non-magnetic, and are often lighter than ferrous metals. Non-ferrous metals are widely used in industries where strength, lightness, and resistance to rust are essential.

Types of Non-Ferrous Metals

Some of the most common non-ferrous metals include aluminum, copper, lead, zinc, and nickel. Each of these metals has unique properties that make them suitable for various applications. For example, aluminum is known for being lightweight and highly resistant to corrosion, making it ideal for aerospace and automotive industries. Copper, on the other hand, is an excellent conductor of electricity, making it essential in electrical wiring.

Properties of Non-Ferrous Metals

Non-ferrous metals tend to be more resistant to corrosion compared to ferrous metals. This makes them ideal for use in environments that are exposed to moisture, such as marine environments or in outdoor applications. They are also typically more malleable, meaning they can be shaped and formed more easily without cracking or breaking.

Another key characteristic of non-ferrous metals is that they are generally non-magnetic. This makes them perfect for applications where magnetic interference could be problematic, such as in electrical equipment and electronic devices.

Ferrous Metal and Non-Ferrous Metal: Key Differences

While both ferrous and non-ferrous metals are essential in various industries, they have distinct differences that influence their use in manufacturing and construction. Let’s examine the key differences between ferrous and non-ferrous metals in terms of properties, cost, and applications.

Composition

The primary distinction between ferrous and non-ferrous metals is their composition. Ferrous metals contain iron as a primary component, while non-ferrous metals do not. This simple difference leads to variations in properties such as strength, corrosion resistance, and weight.

Corrosion Resistance

One of the most notable differences between ferrous and non-ferrous metals is their resistance to corrosion. Ferrous metals are highly susceptible to rusting, especially when exposed to moisture and oxygen. Non-ferrous metals, however, are much more resistant to corrosion, making them better suited for use in harsh environments or applications that require long-term durability.

Weight and Strength

In general, non-ferrous metals are lighter than ferrous metals. For example, aluminum, a non-ferrous metal, is much lighter than steel, a ferrous metal. This makes non-ferrous metals ideal for applications where weight is a critical factor, such as in the aerospace or automotive industries.

However, ferrous metals, particularly steel, are often stronger than non-ferrous metals. This makes ferrous metals the preferred choice for structural applications, such as in the construction of bridges, buildings, and heavy machinery.

Magnetism

Ferrous metals are magnetic due to the presence of iron, while non-ferrous metals are typically non-magnetic. This property makes ferrous metals useful in applications where magnetism is required, such as in the manufacturing of magnets, electric motors, and transformers.

Cost

Ferrous metals are typically less expensive than non-ferrous metals. The abundance of iron in the earth’s crust makes ferrous metals relatively inexpensive to source and process. Non-ferrous metals, on the other hand, tend to be more costly due to their relative scarcity and the more complex processes involved in extracting and refining them.

Applications of Ferrous Metals

Due to their strength and durability, ferrous metals are used in a wide range of applications, particularly in construction and manufacturing. Below are some common uses of ferrous metals:

Construction Industry

Ferrous metals, especially steel, are heavily used in the construction industry. Steel is a key material for building structural components such as beams, columns, and reinforcement bars. Its strength and ability to withstand heavy loads make it essential in the construction of skyscrapers, bridges, and other large-scale infrastructure projects.

Automotive and Machinery

Ferrous metals, particularly steel and cast iron, are commonly used in the manufacturing of automobiles and heavy machinery. These metals provide the strength and durability needed for components like engine blocks, gears, and chassis. The ability to withstand high levels of stress and strain makes ferrous metals the preferred choice in these industries.

Household Items

Many household items are made from ferrous metals, including appliances, kitchenware, and tools. The affordability and strength of ferrous metals make them ideal for items that require frequent use and durability.

Applications of Non-Ferrous Metals

Non-ferrous metals are often chosen for their unique properties, such as resistance to corrosion and lightweight nature. Some of the most common applications of non-ferrous metals include:

Aerospace and Aviation

Aluminum, one of the most widely used non-ferrous metals, is extensively used in the aerospace industry. Its lightweight nature makes it ideal for aircraft construction, helping to reduce fuel consumption and increase efficiency. Non-ferrous metals such as titanium and magnesium are also used in specialized aerospace applications due to their strength-to-weight ratios.

Electrical and Electronics

Copper is one of the most important non-ferrous metals used in electrical wiring and electronics. Copper is an excellent conductor of electricity, making it essential for power transmission and electronic components. Other non-ferrous metals like aluminum and gold are also used in electrical applications for their conductive properties.

Marine and Outdoor Equipment

Non-ferrous metals such as brass, copper, and aluminum are frequently used in marine and outdoor equipment due to their high resistance to corrosion. These metals are ideal for use in environments exposed to water and moisture, such as in boat parts, piping systems, and outdoor machinery.

Conclusion

Both ferrous and non-ferrous metals play vital roles in the manufacturing and construction industries, each offering unique advantages. Ferrous metals are known for their strength and affordability but are prone to corrosion, whereas non-ferrous metals are more corrosion-resistant, lighter, and non-magnetic, though they tend to be more expensive. Understanding the differences between ferrous and non-ferrous metals helps industries choose the right materials for specific applications, ensuring durability, performance, and cost-effectiveness.

When deciding between ferrous metal and non-ferrous metal, it’s crucial to consider factors such as strength, corrosion resistance, weight, and cost to ensure that the material is suited to the intended use.

Need a Steel Construction Company in Terre Haute, IN?

Benchmark Fabricated Steel is a premium service provider for all your metal and steel needs since 1971. We offer an array of services and products for commercial, business, and corporation work. Our fully trained team is available for project design, erect drawings, site construction, product procurement and delivery, engineering and consulting, and much more. Benchmark Fabricated Steel is fully accredited by the AISC and the Canadian welding association allowing for the highest quality product to be produced. Our business is also recognized by the Chamber of Commerce and is a fully certified fabricator. All of our products are manufactured by the highest quality of equipment, with an expert and knowledgeable staff. Contact us today to learn more about what we can do for you!

Categorised in: Products

This post was written by admin