The Benefits of Stainless Steel Fabrication

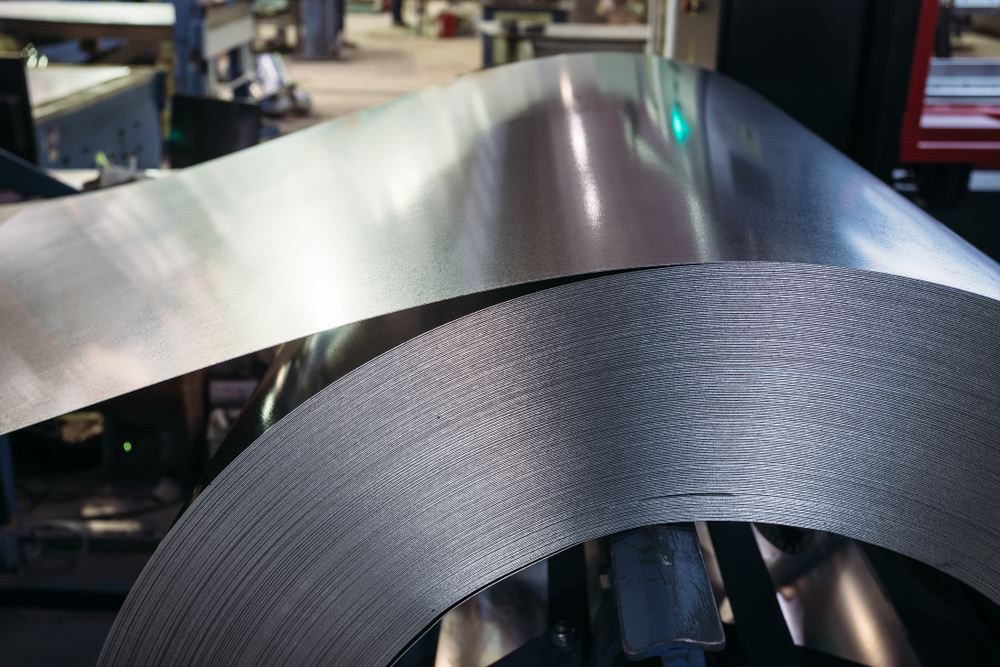

January 3, 2025 4:45 pm Leave your thoughtsStainless steel fabrication is a crucial process in the manufacturing and construction industries, known for its versatility, durability, and aesthetic appeal. It involves the shaping, cutting, and assembling of stainless steel components to create various products used in a wide range of applications. From industrial machinery to residential architecture, stainless steel fabrication plays a vital role in the production of many items we encounter daily. This blog will explore the key benefits of stainless steel fabrication, shedding light on why this material remains a preferred choice for countless industries.

Durability and Longevity

One of the most significant advantages of stainless steel fabrication is the material’s remarkable durability. Stainless steel is known for its resistance to corrosion, oxidation, and rust, which makes it ideal for both indoor and outdoor applications. Unlike other metals, stainless steel does not deteriorate easily over time, even when exposed to harsh environmental conditions like moisture, extreme temperatures, or chemicals.

This robust material ensures that fabricated stainless steel products last for decades without significant wear or damage. For example, stainless steel structures such as bridges, railings, and building facades can withstand the elements for extended periods, reducing maintenance costs and enhancing the longevity of the product.

Moreover, the inherent strength of stainless steel makes it highly resistant to physical impacts. This durability makes it a preferred material in industries like aerospace, automotive, and construction, where safety and longevity are critical considerations.

Aesthetic Appeal and Versatility

Another key benefit of stainless steel fabrication is its aesthetic appeal. Stainless steel has a sleek, modern, and polished appearance that adds a touch of sophistication to any project. Whether used for architectural elements like staircases, countertops, or facades, stainless steel enhances the visual appeal of the finished product.

The material’s versatility extends beyond its appearance. Stainless steel can be fabricated into a wide range of shapes and sizes, making it adaptable to various design needs. From intricate, customized parts to large structural components, stainless steel can be formed to meet specific design requirements, enabling designers and architects to create unique, innovative, and functional products.

Stainless steel’s ability to be molded into various shapes without compromising its strength makes it suitable for diverse applications, including industrial machinery, kitchen equipment, medical devices, and even consumer products like watches and jewelry.

Resistance to Corrosion and Staining

Corrosion is a common issue with many metals, especially in industries where exposure to moisture, chemicals, or saltwater is frequent. However, stainless steel is highly resistant to corrosion, which is one of the primary reasons it is so widely used in fabrication. The material contains chromium, which forms a protective oxide layer on the surface, preventing rust and other forms of corrosion from developing.

This resistance makes stainless steel an excellent choice for outdoor applications, such as marine environments, food processing facilities, and chemical plants. Stainless fabricators can design and create products that will withstand challenging conditions, ensuring that the final product maintains its functionality and appearance over time.

Additionally, stainless steel’s resistance to staining is another advantage. Unlike other metals, stainless steel retains its clean, polished look even when exposed to harsh conditions, making it ideal for applications where hygiene and cleanliness are essential, such as in the medical or food industries.

Hygienic Properties

Stainless steel is a non-porous material, which means it does not absorb dirt, bacteria, or other harmful pathogens. This property makes it an excellent choice for industries that prioritize hygiene, such as the food and medical sectors. Stainless steel surfaces can be easily cleaned and sanitized, helping to prevent contamination and ensuring that the products made from it remain safe for use.

In food processing and preparation environments, stainless steel fabrication is essential for creating equipment like countertops, sinks, and food storage containers that can be cleaned thoroughly without fear of cross-contamination. Similarly, stainless steel is commonly used in medical devices, surgical instruments, and healthcare facilities because it minimizes the risk of infection and contamination.

This hygienic property also extends to the ease with which stainless steel can be maintained. Regular cleaning with non-corrosive detergents is usually sufficient to maintain its surface, which reduces the need for frequent replacements or repairs.

Environmentally Friendly and Recyclable

As concerns about environmental sustainability continue to grow, stainless steel fabrication offers an eco-friendly solution. Stainless steel is a 100% recyclable material, meaning that products made from stainless steel can be reused or repurposed at the end of their lifecycle. This reduces the amount of waste generated in landfills and helps conserve natural resources.

In addition, the recycling process for stainless steel requires minimal energy compared to the production of new stainless steel, making it a more energy-efficient choice. The fact that stainless steel retains its properties even after recycling makes it a sustainable option for many industries.

By choosing stainless steel for fabrication, businesses contribute to reducing their carbon footprint and promoting sustainability. This is especially important in industries that prioritize green building practices and eco-conscious manufacturing processes.

Cost-Effectiveness

While stainless steel may have a higher upfront cost compared to other materials, its long-term value and cost-effectiveness make it an attractive option for many businesses. The material’s durability, resistance to corrosion, and low maintenance requirements mean that products made from stainless steel will have a longer lifespan, which helps businesses save money on repairs and replacements.

Moreover, the strength of stainless steel allows it to perform in demanding environments without requiring frequent maintenance or replacement parts. This reduces downtime and the associated costs in industrial settings, where machine failure can lead to significant losses.

For example, in the food processing industry, stainless steel equipment’s resistance to corrosion and ease of cleaning contribute to a longer service life, meaning fewer replacements and a better return on investment over time.

Customization and Precision

Stainless steel fabrication offers a high degree of customization and precision. Skilled stainless fabricators use advanced techniques such as welding, cutting, and bending to shape the material into precise components tailored to specific needs. This ability to create custom-designed products allows businesses to meet their unique requirements without compromising on quality.

Whether it’s creating intricate components for machinery or designing bespoke architectural features, stainless steel fabrication ensures that the final product aligns with the exact specifications. Additionally, modern fabrication methods allow for tight tolerances and complex geometries, making stainless steel ideal for industries that require high levels of precision, such as aerospace and electronics.

Conclusion

Stainless steel fabrication offers numerous benefits that make it an essential material in a wide variety of industries. Its durability, resistance to corrosion, aesthetic appeal, and hygienic properties make it an ideal choice for many applications, from architectural structures to industrial machinery. Additionally, its sustainability, customization options, and cost-effectiveness add to its value, making it a long-term solution for businesses looking for high-performance materials.

As the demand for sustainable, durable, and aesthetically pleasing products continues to grow, stainless steel fabrication remains at the forefront of material innovation. By working with skilled stainless fabricators, businesses can take advantage of all the benefits that stainless steel has to offer, ensuring high-quality, reliable, and cost-effective solutions for years to come.

Need a Steel Construction Company in Terre Haute, IN?

Benchmark Fabricated Steel is a premium service provider for all your metal and steel needs since 1971. We offer an array of services and products for commercial, business, and corporation work. Our fully trained team is available for project design, erect drawings, site construction, product procurement and delivery, engineering and consulting, and much more. Benchmark Fabricated Steel is fully accredited by the AISC and the Canadian welding association allowing for the highest quality product to be produced. Our business is also recognized by the Chamber of Commerce and is a fully certified fabricator. All of our products are manufactured by the highest quality of equipment, with an expert and knowledgeable staff. Contact us today to learn more about what we can do for you!

Categorised in: Steel Fabrication

This post was written by admin